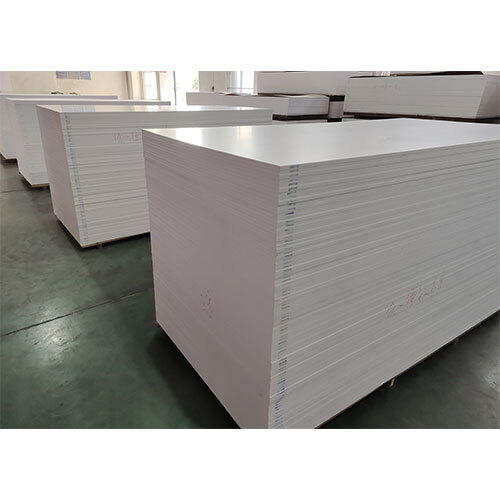

About PVC WPC Foam Boards Sheets Density from low and high

Procure Commanding PVC WPC Foam Boards Sheets with flawless density options from 0.45 to 0.80 g/cm3. Engineered for excellence, these boards offer self-extinguishing fire resistance (B1 standard), <1% water absorption, E0 formaldehyde emission, and moisture resistance rated as excellent. Their matte, smooth, or textured surface finish elevates every project. Try Now - perfect for furniture, wall cladding, partitions, modular kitchens, and more. Get It Now in customizable sizes, colors, and edge finishes. Eco-friendly, lead-free, rigid, and UV-resistant, they ensure safe, reliable, and sustainable use for distributors, exporters, and service providers.

Versatile Applications & Competitive Edge

PVC WPC Foam Boards Sheets present a commanding application surface, available in matte, smooth, and textured finishes for general or specific uses including furniture, interior partitions, wall cladding, and signage. Their competitive advantages include flawless moisture and fire resistance, non-toxic E0 formaldehyde emission, and environmentally-safe material, making them ideal for humid environments. Procure these sheets in various densities, ensuring durability and versatility for all your design needs.

Sample Policy & Export Logistics

Freight, drop-off, packing, and dispatch are managed meticulously, ensuring fast, safe deliveries. Our sample policy lets you try these sheets now before bulk procurement. With strong presence in main export markets such as Asia, Europe, and the Middle East, and robust domestic distribution across China, we ensure competitive logistics and export standards. Standard export packing or customizable packing options are available, demonstrating our flexible and reliable service for global and local clients.

FAQ's of PVC WPC Foam Boards Sheets Density from low and high:

Q: How do PVC WPC foam boards perform in high-moisture environments?

A: PVC WPC foam boards exhibit excellent moisture resistance, making them ideal for humid locations such as kitchens, bathrooms, and laundry areas. Their surface remains unaffected, preventing warping and deterioration over time.

Q: What processing methods can be used with these foam boards?

A: These boards can be sawed, drilled, nailed, and machined with standard woodworking tools. Their rigid composition ensures flawless fabrication, whether for furniture, partitions, or signage applications.

Q: When should I choose high-density versus low-density PVC WPC foam boards?

A: High-density boards (up to 0.80 g/cm3) are best for projects requiring extra strength and durability, such as heavy-duty furniture or structural partitions. Low-density boards (0.45 g/cm3) are lightweight and suitable for general signage or temporary wall cladding.

Q: Where can customized sizes, colors, and edge finishes be requested?

A: Customized options including size, color (white, brown, grey, and custom), and edge finishes (square, rounded, custom) can be requested during placement of orders. Please consult with our sales team to specify your requirements.

Q: What are the main benefits for distributors and fabricators?

A: Distributors and fabricators benefit from reliable quality, eco-friendliness (100% recyclable and lead-free), flawless surface finishes, and competitive export packing tailored for efficient logistics and safe delivery worldwide.